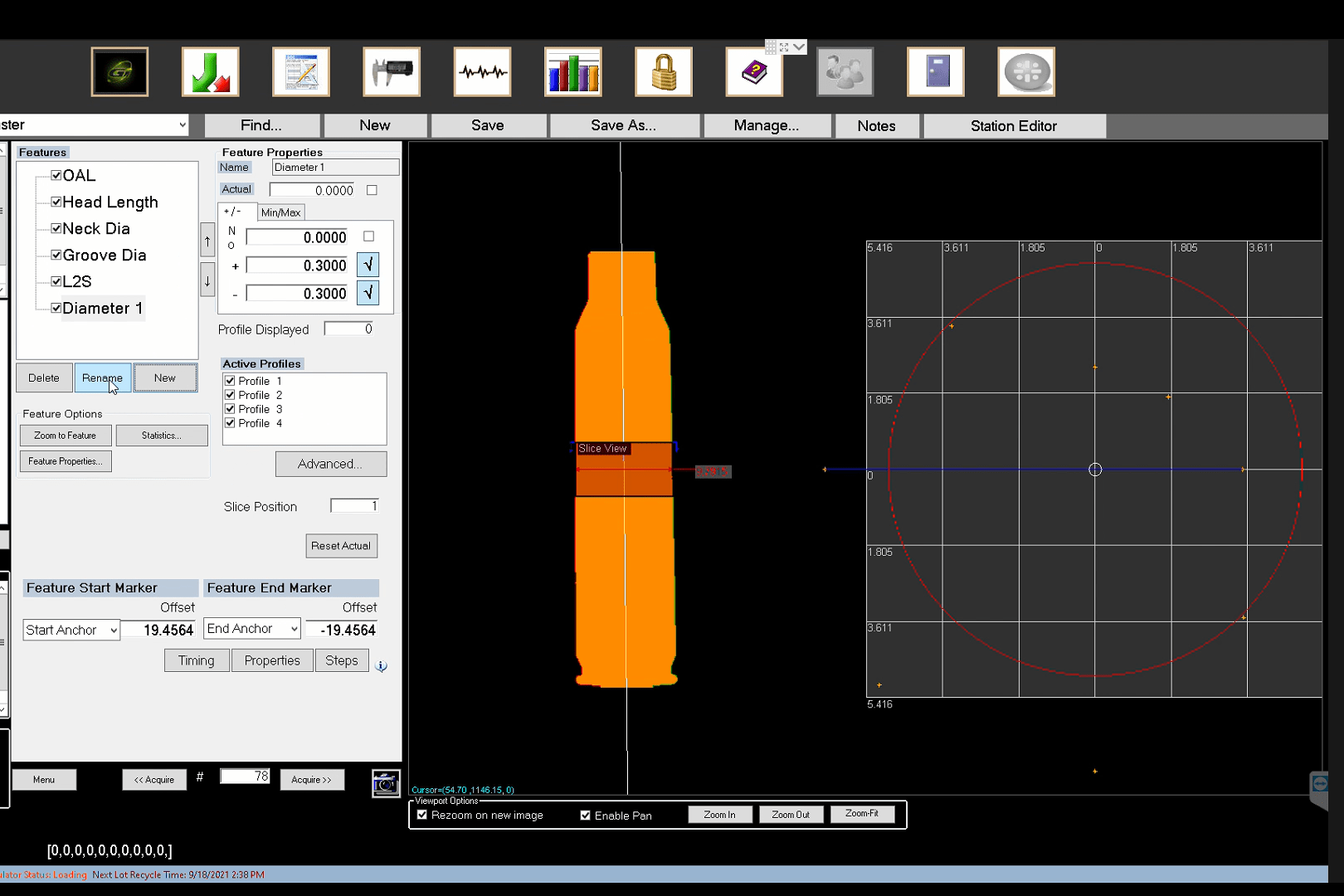

The Gi-360T-SD is a 3D high speed laser gauging and inspection machine. Precision split/narrow laser beams, multi laser velocity gauges are used to accurately measure parts to print tolerances. It uses 3D data from multiple laser beams to detect defects that may only be on one side of the part such as dents. In addition to dimensional inspection capabilities, SD Vision provides 360o surface defect detection for defects such as porosity, stains, cracks, plating and color variations. Four off axis cameras simultaneously image parts as they are illuminated with Gi’s unique lighting technique.

Gi-360T-SD Automotive Applications

High speed measuring of all critical external features and visual defect detection utilizing laser gauging and SD vision.

Laser Gauging

Provides 360° dimensional measurement of complete profiles including:

Detects

• Lengths

• Threads

• Diameters

• Hex Flats and Corners

• Tapers

• Radii

• Concentricity

• Straightness

SD Vision

Four camera station provide full 360° surface inspection. Used to detect damage around the part circumference. Proprietary software running on dedicated vision servers analyzes part images in real-time.

Detects

• Visual Defects

• Dents

• Scratches

• Acid Burn

• Perforations

• Wrinkles

• Chips